Components control

It starts when we receive the goods. We make a quantity check and a first quality inspection

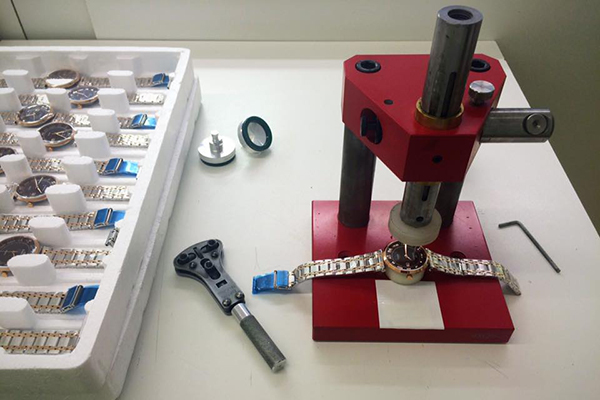

Sample pieces

Just to be on the safe side, we always assemble 10 sample pieces that will be submitted to our client. This way the client can check that everything meets his expectations.

Working process

Our working process is developed in sequence.

This way we can have fast working times and skilled, trained and qualified staff.

The pieces are handmade, posing of the dial and hands.

At the same time a quality control of the single components is carried out during these stages.

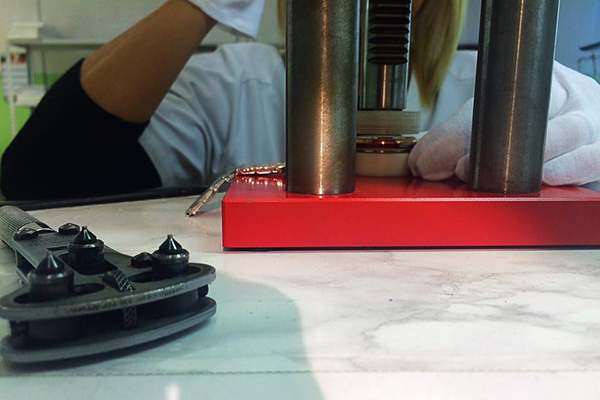

Casing

Casing is made by using air compressed and vacuum systems, which help our staff in this process.

Closing of the various types of casebacks is handmade.

Screw down casebacks is made by means of a machine that helps screw and unscrew the backs.

ATM test

Every single watch undergoes an ATM test, in order to test its water impermeability endurance.

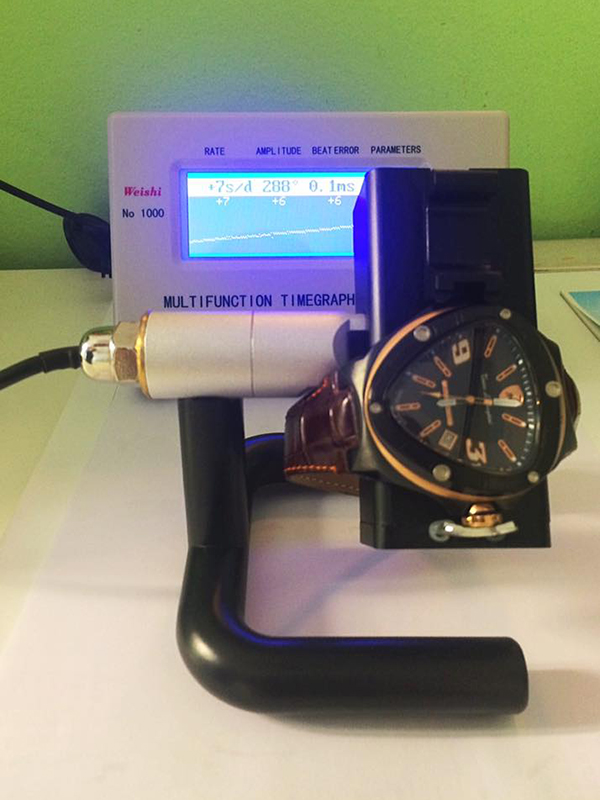

Proper functioning control

Quartz movement watches are checked at least for 48hours, on both sides.

Automatic selfwinding movements are handwinded and controlled at full energy.

The second check is made 24 hours after the piece is closed, in order to establish its correct functioning.

Once this inspection is made, the bracelet is assembled.

Quality control

Terna SA can work with any kind of material and movements as we are specialized in chronographs, automatics, and complicate movements.

The quality control is both for the aesthetic and the technical features, and, depending on our clients’ requests it’s possible to add more tests and controls.